What You Need to Know About Custom Design Components' New Deburring Machine

For many years now, CDC has been using a deburring process known as thermal deburring as a way to ensure that all chips and burrs are removed from the manifolds that we sell. Thermal deburring is a process where the manifolds are sealed into a chamber that is then filled with a gas mixture and ignited with a spark. The burning gases in the chamber create a very intense heat wave that travels through the manifold and effectively burns off any metal that is not a the part of the manifold itself- particularly any loose chips or fine metal shavings.

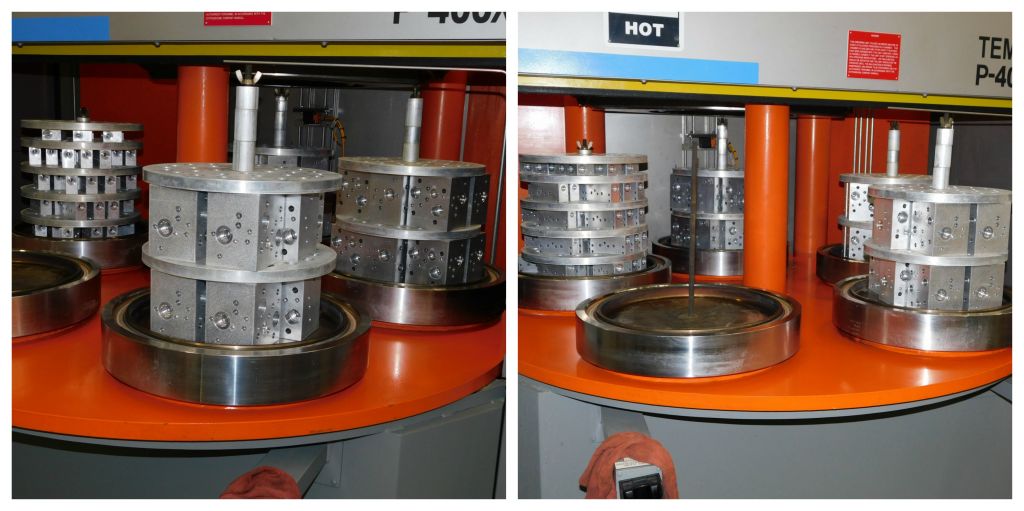

This process has been used with great success here at CDC for many years, and we are now proud to say that we have brought this exciting deburring method under our own roof by purchasing an Extrude Hone P-400 XL Thermo Bur machine. This is the largest capacity machine that Extrude Hone produces with a chamber volume of 15” x 18.5”, allowing us to process the great majority of the parts that our customers require. We are equipped to process aluminum as well as steel and cast iron manifolds.

If you would like any more information on the capabilities of this machine or ask why you should insist that this deburring method be incorporated into the manifolds that you supply to your customers, please do not hesitate to contact us today!